Max Oakes was five years old when his dad, Dan Oakes, hoisted him into a bulldozer, so they could take down an old storage building. “We just ran right through it. It was at that moment I knew I wanted to be part of the construction industry.” Today Max is a major part of it. President of A. W. Oakes & Son, Inc., he’s poised to assume the helm when current owner Dan Oakes retires. In fact, Max oversees two Oakes companies— A.W. Oakes & Son, which owns all of the “big iron” that’s highly visible doing reconstruction; and Oakes Transportation, which handles DOT regulated vehicles (pickup trucks, dump trucks, lowboys, and concrete mixers) and employs the mechanics and drivers. A Marquette graduate with accounting and finance degrees and his CPA, Max spent his first eight years focusing on company financials, preparing to one day assume ownership.

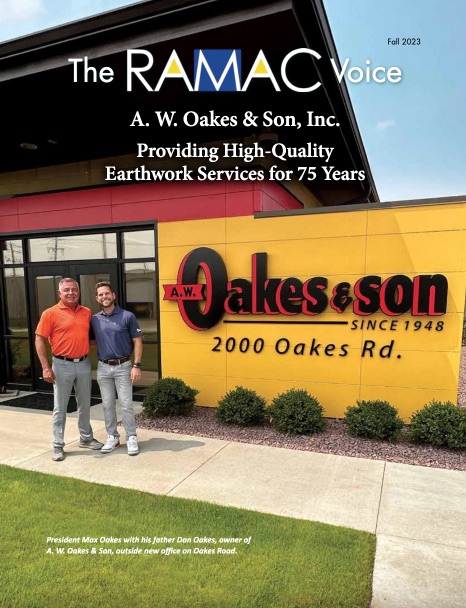

Although this is A. W. Oakes 75th year since incorporation, Dan, Max and their 200+ employees don’t find a lot of time to celebrate. They recently completed a 7,000 sq. ft. office space on Oakes Road, partnering with Bukacek Construction. The concrete reconstruction of much of Goold Street and Durand Avenue was completed last year along with the grading and utility development of multiple large warehouse facilities in Racine and Kenosha Counties. The grading and installation of utilities and concrete lanes of Paddock Lake’s Main Street and Moorland Road in New Berlin are two of their largest, ongoing projects. The vast majority of their projects focus on Racine and Kenosha, no further west than Lake Geneva or north of Milwaukee. “The locations we serve are in a small area,” says Dan. “But it’s growing and will continue to grow, so we’re committed to maintaining the infrastructure while picking up new projects, all while staying local.”

History

History

A. W. Oakes’ actual roots trace back to the 1930s when Dan’s grandfather, Arnold William Oakes, came out of the armed services. One of his first grading jobs was the early stages of Bong Airfield Base in Kenosha County. As Dan recalls, “He was already into heavy equipment, moving 55-gallon drums of diesel in the back of a pickup truck.” By the 1950s, Dan’s father Glenn was in the business with his dad. “I still hold on to my grandmother’s log books and old checks from the family’s initial business.”When Glenn completed military service, he joined the Oakes family business, then it became A. W. Oakes & Son, Inc. Devotion to a family-operated business was evident then and still is. Dan and Max agree, “The name A.W. Oakes & Son remains today, and it always will.”

Hitting 75 years in business is no small feat. Certain factors contribute to a company’s success and longevity. For A.W. Oakes & Son it’s 1) family and keeping them safe, and 2) embracing change and innovation—always moving forward.

People Focused

As its name suggests, A. W. Oakes & Son is a family-oriented company, something Dan and Max Oakes are committed to. “We take on projects within a 1-hour radius—although the majority are much closer—so workers can be home at night with their families; able to go to their kids’ ball games, not wishing they were from some hotel room or trailer four or five nights a week. As a result, we have second and even third generations of families in our workforce. We’re firm believers in the theory "Happy at home; Happy at work.”

Keeping People Safe

A. W. Oakes & Son is also committed to keeping every worker safe. To ensure that a full-time safety coordinator was hired four years ago. She visits every job site throughout the week and talks to the foreman and the guys in the field to ensure all are safe and have the proper PPE (Protective Personal Equipment). If there’s an issue, a “stand down” stops all work, the issue is discussed and once resolved, work begins again. The new office addition includes a large safety training room where employees get toolbox talks and other essential safety training. As Safety Director, Max sees that the company focus on safety has greatly reduced the severity and frequency of accidents. When they do happen, a root cause analysis is done with the project manager and foreman to identify what went wrong and how to avoid it in the future.

Change and Innovation

At A. W. Oakes, keeping up with technology is a constant effort. The technology department along with college interns explore ways to benefit from Artificial Intelligence (AI) and innovations in smart equipment and AutoCAD soft ware technology. “We’ve virtually eliminated hand staking where a guy draws a sharpie line on a stake and equipment pushes the dirt up to that line,” says Dan. “Now the bulldozers, graders, excavators and concrete pavers are equipped with satellite-controlled GPS systems, so operators see everything on a screen. If we’re putting curbs in for a parking lot, we can start out in a gravel lot with nothing marked and put curbing in at the proper height without one stake. The stringless operation is safer since no one is tripping over things and trucks can pull in anywhere.” Stringless also saves on large amounts of unnecessary manual labor, saving shoulders and backs, while reducing tripping hazards from removing string.”

A. W. Oakes benefits from the strong partnerships they have with equipment manufacturers like Komatsu. They had the opportunity to test drive two new bulldozer models—the first in the US to do so—and provide feedback. Recently A. W. Oakes engaged drones to fl y for site surveying and photographing their jobs, reducing manual surveying ti me while increasing accuracy when the situation applied. Over the years many local enterprises have benefited from A. W. Oakes’ charitable donations, including the Racine Zoo, Saint Catherine’s and other schools, Gateway Technical College, the RPD’s Policeman's Ball, Prairie School, the Racine Parks Department, and youth sports teams, to name a few. It’s just part of our Tradition of Quality,” says Dan. “Whether it’s improving infrastructure, reclaiming brownfields or donating benches to a school, we are here to help the community to be a better place.”

Article taken from RAMAC Voice, Fall 2023

Written by Maureen Bagg